What is a Casing Chamber?

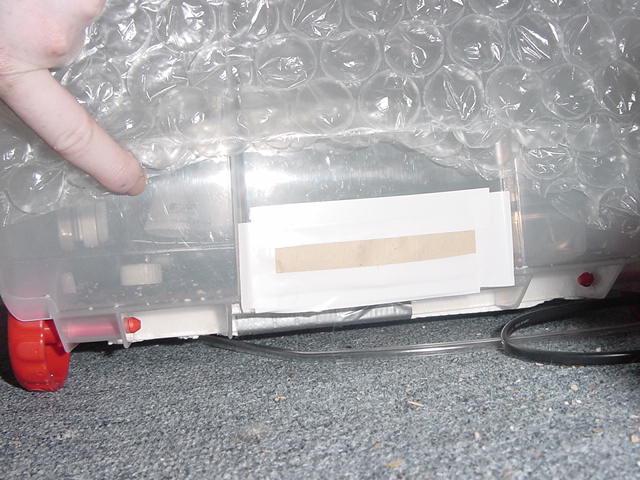

Bubble wrapped for heat retention

Casings require different growing conditions to cakes.

A casing needs humidity to be kept at a constant 85% (roughly) and temperatures between 73-77F.

At humidities higher than 85% you will find the casing layer more prone to contamination and the casing needs to be able to evaporate moisture from the casing layer to aid pinning and keep the micro-atmosphere contained in the casing at optimal levels for the development of the mushrooms.

Perlite is not used in casing chambers as this would tend to keep the humidity levels too high for a casings needs.

The reptile heating pad is clearly visable through the bottom of the terrarium. It is better to mount the pad on the inside of the chamber but precautions when using anything electrical need to be observed. There will be moisture present inside the chamber so some form of protection for the electrical connections need to be in place. If silicone sealant is used be sure to apply it when the pad is disconnected from the supply and the sealant is allowed to cure for at least 24hrs before use.

A beaker of water is placed in the terrarium and moved on/off the reptile pad until the desired humidity is reached.

Also the casings are placed on a wire 'cake stand' to keep them from being in direct contact with the reptile pad.

You will see the two long, green 'airstones' that are connected to an air pump for a fresh air supply. A digital hygro/thermometer is used for monitoring the environment. The dark dust which seems to be covering everything are mushroom spores...the chamber should be cleaned regularly.

Vent holes are added as an exhaust for CO which builds up as the mushrooms/mycelium are growing. The CO is forced out of the exhaust holes when the air pump introduces fresh air into the chamber. CO is heavier than air and so sinks to the bottom of the chamber.

The holes were 5x5mm and covered with a coffee filter paper on the outside. This reduces the need for hand fanning although I would recommend giving it a good hand mist once a day or more if you have a small pump. |